which is a type of machine safeguarding

However when employees need to pop the guard open to deal with maintenance and repairs interlocking guards are very accommodating. A machine guarding means any enclosure barrier or device constructed to prevent a person from coming in contact with dangerous parts of the machine.

In August 2018 Google Incorporated Voice Navigation In The Navigational Platform For Pu Navigation System Information And Communications Technology Navigation

A Pullback devices b Safety trip controls c Electro-mechanical sensing device d Two-hand control.

. An interlocking guard provides a reliable barrier over moving machine parts. When the operation of. A well-designed fixed guard will also prevent the operator from reaching over or under the guard into the point of operation.

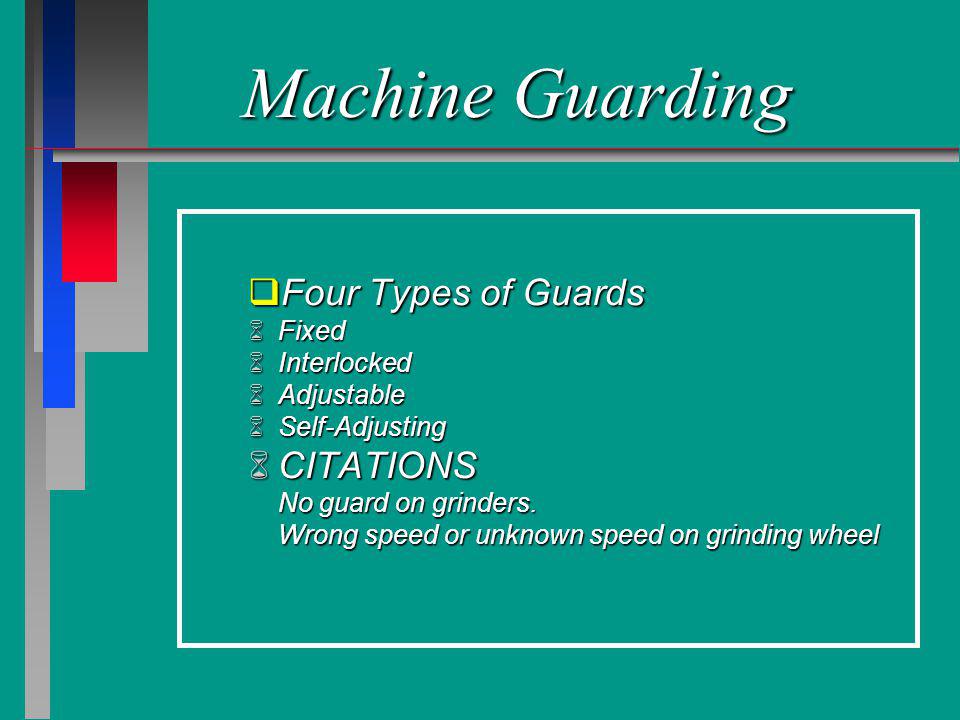

An interlocking guard provides a reliable barrier over moving machine parts. There are four types of machine guards installed on a machine. Basics of Machine Safeguarding.

The following are all machine safeguarding requirements except. A safety device may perform one of several functions. They are made up of material capable of withstanding force sharp edge and moving part impact.

Fixed Adjustable Self-Adjusting Guards. Plus interlocking guards automatically shut off a machines power source when employees open them. Machine safeguarding helps protect workers from preventable injuries in all three areas.

Wrists are connected by cords and secured to a fixed anchor point which limit operators hands from reaching the point of operation at any time. These can include everything from controls that require the worker to use both hands gates that block access to moving parts and sensing devices that identify when the worker is too close. Mechanical Engineering questions and answers.

Fixed interlocked adjustable and self. Interlocked guard when opened. The types of waste include processes activities products or services that require.

Which of the following is the definition of point of operation. These can include everything from controls that require the worker to use both hands gates that block access to moving parts and sensing devices that identify when the worker is too close to the hazard. Contents hide 1 Fixed guards.

These include fences gates and protective covers for blades presses and all moving parts. Moving machine parts have the potential to cause severe workplace injuries such as crushed fingers or hands amputations burns or blindness. In the worst of all cases the machine can do to your body parts what its doing to.

It may stop the machine if a hand or any part of the body is inadvertently placed in the danger area. The purpose of machine guarding is to protect the machine operator and other employees in the work area from hazards that occur during normal machine operation. Types of machine guarding.

Dangerous moving parts in three basic areas require safeguarding. Also know what are the most common types of machine guarding. Most usable machine guards are described below.

Which of the following is a type of machine safeguarding punchink feeding and ejection methods point of operation in-going nip points Feeding and ejection methods is a type of machine safeguarding. Require the operator to use both hands on machine controls thus keeping both hands and body out of danger or provide a. 3 Fixed adjustable access guard.

Best practices say to apply this same rule to all types of equipment. Which of the following is a type of machine safeguarding. A fixed guard is a simple device attached to the machine designed to cover hazardous mechanical motions and prevent entry.

It should fail-safe and be an interlocking type. There are five 5 general types of machine safeguards that can be used to protect workers and personnel in the immediate vicinity of machinery. Our Machine Guarding Safety Training course is regulation compliant and our online version fulfills classroom training requirements.

Similarly what are the 2 types of primary safeguarding methods. Which of the following is a type of machine safeguarding. Machines can cause a variety of.

All machines consist of three fundamental areas the point of operation the power transmission device and the operating controls. The most common types of machine guards are. Their suitability should be selected.

Fixed guard provides a barrier between a person and the point of opera power train or other moving parts. Interlock into the machines control system to stop operation when the sensing field photoelectric radio frequency or electromagnetic is disturbed. Must prevent workers from lubricating a machine without removing the safeguard.

2 Fixed limited access guards. Which of the following is a type of machine safeguarding. Types of Machine Guarding Restraint Devices.

A fixed guard is a simple device attached to the machine designed to cover hazardous mechanical motions and prevent entry from hands or fingers. Also asked is punching a type of machine safeguarding. Herein what are the most common types of machine guarding.

Machine safeguarding helps protect workers from preventable. Primary Safeguarding Methods Two primary methods are used to safeguard machines. This course introduces the student to the basic concepts and principles for machine safeguarding as described by OSHA in 1910 Subpart O Machinery and machine guarding.

Primary Safeguarding Methods Two primary methods are used to safeguard machines. Each class contains sections on equipment operations hazards case studies and more. Which of the following is an exception to the general rule for safeguarding to prevent hazards during servicing and maintenance of machines.

Guards these are physical barriers that prevent contact. A so-called free-pass cannot be awarded. The Occupational Safety and Health Administrations OSHAs requirements for machine guarding are found in 29 Code of Federal Regulations CFR 1910 Subpart O Machinery and Machine Guarding as detailed below.

Various types of machine guards available for machine guarding. Any machine part function or process that may cause injury must be. Safeguards are essential for protecting workers from these preventable injuries.

Feeding and ejection methods. All of the above Which of the following is a type of machine safeguarding. What is safeguarding of machinery.

Ergonomics of Machine Guarding. Safeguarding devices which encompass a variety of equipment that prevents or limits access to the hazards. Guards on the machines act as a barrier between humans and different machine parts.

Restrain or withdraw the operators hands from the danger area during operation. It may stop the machine if a hand or any part of the body is inadvertently placed in the danger area. Lets dive into the four types of machine guards.

OSHA Safety and Health Information Bulletin SHIB January 25 2013. Ergonomics is the studying measuring and organizing the work. Types of Machine Guards.

Pin On Home Appliances Collection

Heidelberg Printer Heidelberg Prints Offset Printing

Wholesale Commercial Gym Equipment 6 Important Items To Look For When Buying Gym Equipment Gym Commercial Gym Equipment Gym Equipment

An Overview Of The Generic Standards A B Standards Pilz Int

Crane Balancing Act Truck Cranes Crane Construction

Four Types Of Fixed Machine Guards

Gaggia 90500 Titanium Super Automatic Espresso Machine Silver Automatic Espresso Machine Cappuccino Machine Espresso Machine

Oshacademy Course 154 Machine Safeguarding Basic Module 2

Best Whirlpool Refrigerator Service Centre In Hyderabad Refrigerator Service Whirlpool Refrigerator Whirlpool Fridges

Four Types Of Fixed Machine Guards

Machine Guarding Four Types Of Guards Citations Fixed Interlocked Ppt Video Online Download